Aero-tec provides the industry’s most comprehensive line of spray booth products and systems for its global base of general industry and manufacturing customers. Complimented by state-of-the-art, flexible and cost-effective solutions, Aero-tec is the preferred source for finishing process equipment. All Aero-tec products are designed with one common goal: the ability to produce a superior quality finish in the most efficient manner.

Aero-tec provides the industry’s most comprehensive line of spray booth products and systems for its global base of general industry and manufacturing customers. Complimented by state-of-the-art, flexible and cost-effective solutions, Aero-tec is the preferred source for finishing process equipment. All Aero-tec products are designed with one common goal: the ability to produce a superior quality finish in the most efficient manner.

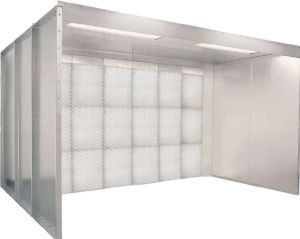

Aero-tec spray booths feature a modular design. This approach offers the economy of a standardized line of spray booths while making available a variety of sizes and configurations to fit a broad range of finishing processes. Custom designs are available including white pre-coated, or zinc galvanized panels.

Improved Room Ventilation and Controlled Overspray Flow

Aero paint rooms have gone through intensive FEA analysis in order to optimize the room ventilation process. The location of air inlet, outlet, and air volume flow rates have been carefully determined in order to enhance the paint transfer efficiency, paint layer finish, operator efficiency and work piece visibility. The overspray paint is moved away from your work piece and held by filters for disposal.

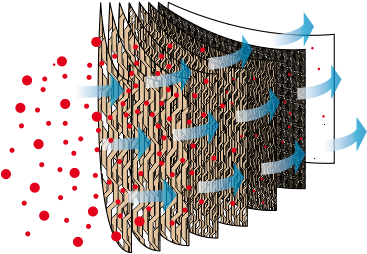

Filter System

Filter System

Using the unique Inertia Separation Principle the majority of over spray are retained outside the airstream inside the filter itself. This keeps the airflow through the filter clear as well as capturing the overspray particles for easy disposal.

Intensive lighting for optimum visibility

Reaching to the difficult areas in your work piece, and finding any paint defects cannot be improved without the brilliant light distribution and luminance. The rooms are designed to be equipped with special types of paint rooms lightings for a maximum productivity and safety.