Aero-tec’s flexible approach to design means that we can convert an enclosed work bay into a fully functional spray booth, complete with spray and bake cycle, for a fraction of the cost of an equivalent standalone spray booth. All conversions are specifically designed to suit the individual requirements of each site.

Aero-tec’s flexible approach to design means that we can convert an enclosed work bay into a fully functional spray booth, complete with spray and bake cycle, for a fraction of the cost of an equivalent standalone spray booth. All conversions are specifically designed to suit the individual requirements of each site.

No matter what your production volume, product size requirements or workflow requirements, we can tailor a superior system to your specific operation for your specific budget. This system solution will contribute to your company’s cash flow by reducing costs and achieving the efficiencies designed into total finishing quality control.

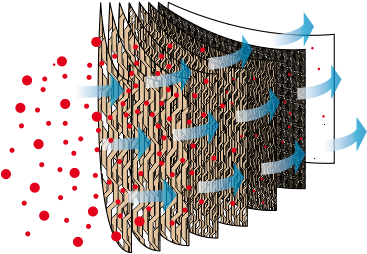

Improved Room Ventilation and Controlled Overspray Flow

Aero paint rooms have gone through intensive FEA analysis in order to optimize the room ventilation process. The location of air inlet, outlet, and air volume flow rates have been carefully determined in order to enhance the paint transfer efficiency, paint layer finish, operator efficiency and work piece visibility. The overspray paint is moved away from your work piece and held by filters for disposal.

Filter System

Filter System

Using the unique Inertia Separation Principle the majority of over spray are retained outside the airstream inside the filter itself. This keeps the airflow through the filter clear as well as capturing the overspray particles for easy disposal.

Intensive lighting for optimum visibility

Reaching to the difficult areas in your work piece, and finding any paint defects cannot be improved without the brilliant light distribution and luminance. The rooms are designed to be equipped with special types of paint rooms lightings for a maximum productivity and safety.

Baking cycle requirements

Baking cycle requirements

Heating of the room for baking and fast curing is an option for many customers depending on their industry requirements. We can provide direct-fired gas or propane burners, or indirect fired oil burners, to regulate spray temperatures and provide a low bake cycle.

An air handling unit supplies tempered and filtered air to the booth, minimizing temperature variations and removing particulates that compromise finish quality. Aero can configure an air make-up unit or system that provides heated and filtered air to replace the warm air exhausted by the paint booth.