A room with generous lighting and ventilation for maximum Operator comfort and optimum work performance. Where media is cost effectively reclaimed and reused, not wasted as it is by other systems.

A room with generous lighting and ventilation for maximum Operator comfort and optimum work performance. Where media is cost effectively reclaimed and reused, not wasted as it is by other systems.

Aero Blast Rooms give you all this plus a whole lot of additional built-in features.

Room Sizes

Our blast rooms are customized to any room size. Whether you have the room and you just require our equipment and engineering, or you are looking for a complete system including the room. Room sized can start from 3 x 3 meters floor size up to unlimited range of room sizes. The construction of the rooms can be from different types of materials. Masonry, Sandwich Panels, or Steel panels and structure – our equipment can fit together to give you a state of art blast room.

Blasting equipment

The blasting equipment are ready to be used with any kind of abrasives, a fast response remote control system, a long hose for reaching all the areas of the blast room with minimal loss of pressure, and an efficient abrasive control valve.

Intensive lighting for optimum visibility

Reaching to the difficult areas in your work piece cannot be improved without the brilliant light distribution and luminance. The rooms are designed to be equipped with special types of lightnings for a maximum productivity.

Improved Room Ventilation

Improved Room Ventilation

Aero blast rooms have gone through intensive FEA analysis in order to optimize the room ventilation process. The location of air inlet, outlet, and air volume flow rates have been carefully determined in order to enhance the operator efficiency and visibility. Laden dust and contaminations are kept to its lower level and away from the work piece.

Room Lining

To ensure the rigidity of your bounced back abrasives, and blasting noise attenuation. The room linings are selected to limit the environmental impact over the surroundings whether it is inside or outside the factory.

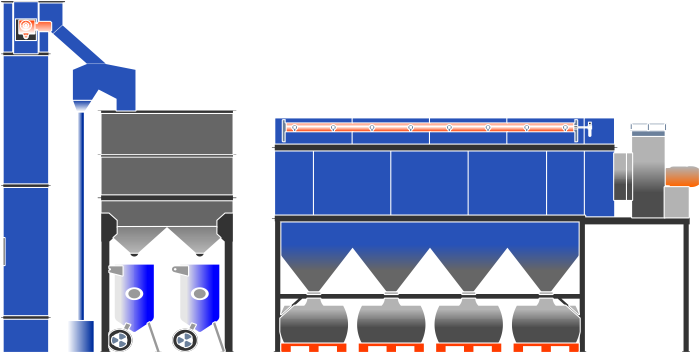

Self cleaning dust collector provides super ventilation for maximum productivity

Clean room and clean environment. Ensure the optimal visibility and working conditions while your operator feels comfortable in operation. The ventilation of the room has been improved to ensure laminar flow inside the room and to avoid flow turbulences.

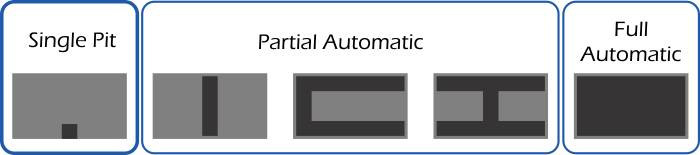

Choose from the different floor types

The different floor types are designed to suit different production capacities and methods. If floor sweeping time is tolerated, then you can go with a single pit or a partial automatic floor. For a more busy production, the full automatic floor is the right solution.

Abrasive Storage hopper

Our storage hopper is a free-standing hopper which is reinforced with structural steel. The hopper position is above the blast tank assemblies to provide easy access to the blast tanks for maintenance.

Cost savings are exceptional with our reclaim and recycling system

Abrasives are the main consumables of your blast room. Ensuring the optimal use of your abrasive starts with proper selection of floor type and recycling system. The whole reclaim and recycling system has been designed to eliminate down time costs and improve productivity, and equipped with a dedicated dust collector.